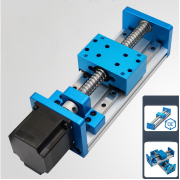

Description

For more detailed information about Linear Modules, please visit https://www.fodabearing.com.

⚙️ Advantages:

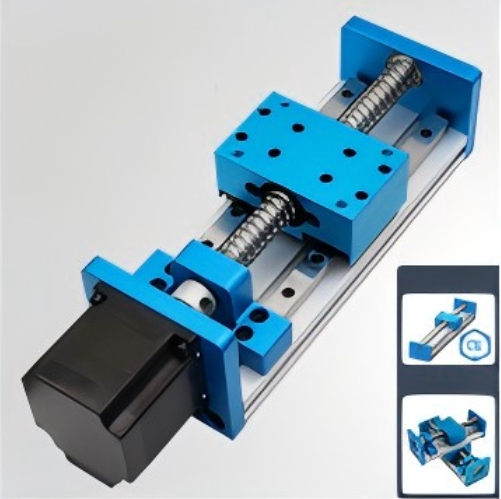

High precision:the rolling contact method of ball screw can effectively reduce friction and provide high precision transmission.

Low friction: Compared with ordinary common screws, ball screws have less friction, which can reduce energy consumption.

High Load Capacity:Ball Screws are able to withstand large loads and are suitable for heavy-duty applications.

⚙️Product Features

High Positioning Accuracy

The ball screw drive mechanism ensures exceptional positioning and repeatability accuracy. This makes it ideal for applications demanding micron-level precision, such as semiconductor production, CNC machining, and robotics.

Excellent Load Handling & Rigidity

The module is integrated with high-rigidity linear guides and precision-ground ball screws. It delivers outstanding load-bearing capacity and axial rigidity. Even under heavy-duty or high-speed conditions, it ensures reliable performance.

Quiet & Smooth Motion

Engineered for low-friction movement, the module offers quiet and vibration-free operation. This makes it ideal for cleanrooms, laboratories, and applications with strict acoustic requirements.

Long Lifespan and Low Maintenance

This linear module is constructed from durable, wear-resistant materials and equipped with a sealed structure to prevent contamination. It ensures long service life and minimal downtime.

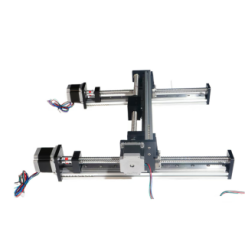

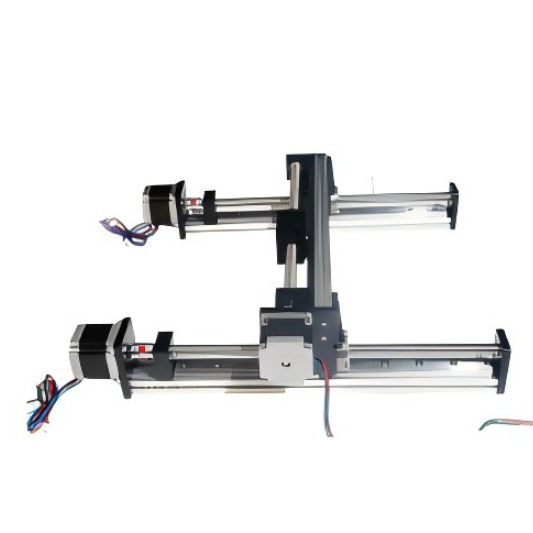

Flexible Modular Integration

The module is available in a wide range of stroke lengths, mounting orientations, and motor configurations. It is designed to seamlessly fit into diverse automation setups with minimal engineering effort.

Wide Industry Applications

It is trusted across a range of industries, including laser processing, electronics assembly, medical automation, precision packaging, and more. These are the places where precision, speed, and stability are essential.

⚙️Application Areas:

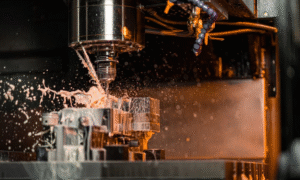

Machine tool industry: In CNC machine tools, such as milling machines, lathes, drilling machines, etc., screw linear modules are used to accurately locate and cut processed workpieces, which can achieve high-precision and high-efficiency metal processing.

Automation equipment field: commonly used in automated production lines and robots, such as material handling, positioning and fine-tuning of processing equipment on the assembly line, which can ensure the precise transmission of materials and precise operation of equipment.

Precision Instrument Manufacturing: In optical instruments, measuring instruments and other precision equipment, the screw linear module provides smooth and precise linear motion to meet the demand for high-precision adjustment, which helps to improve the measurement accuracy and performance of the instrument.

Medical equipment industry: Specifically, it is applied to medical equipment and surgical instruments, such as the automatic insertion and fine adjustment of endoscopes, the position adjustment of surgical beds, and so on. In turn, this achieves fine displacement control, thereby providing more accurate and stable support for medical operations.

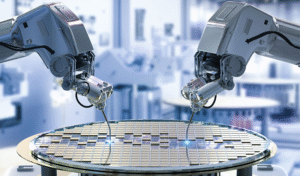

Semiconductor manufacturing field: In chip processing, placement and testing equipment, screw linear modules play a key role in precision positioning, ensuring high precision and efficiency in the semiconductor manufacturing process.

Packaging machinery: It is used to achieve precise unfolding and positioning of packaging materials, improve packaging efficiency and precision, and ensure the quality and consistency of product packaging.

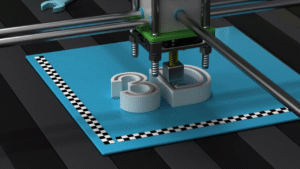

3D Printing Equipment: It can realise the precise movement of the print head, which helps to improve the printing accuracy and quality, and meet the printing needs of complex shapes and high-precision models.

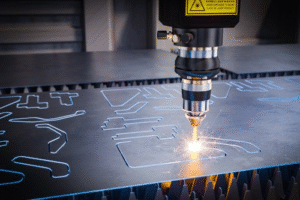

Laser processing equipment: In laser cutting machines, engraving machines and other equipment, we control the position and speed of the laser head to make the laser processing process more accurate and efficient, and improve processing quality and efficiency.

Reviews

There are no reviews yet.