Description

⚙️Product Description

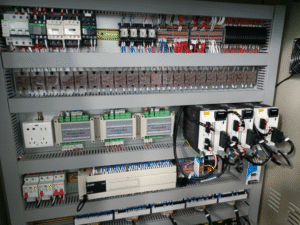

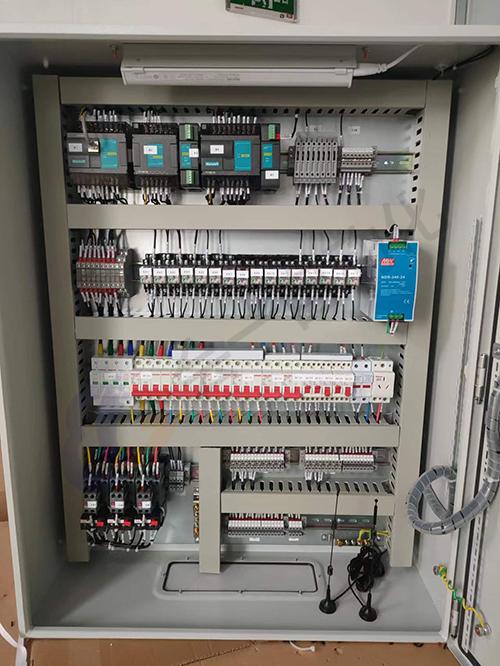

PLC control cabinet is a highly intelligent control equipment.

It adopts advanced PLC technology to achieve precise control and automatic management of industrial production process.

The appearance design is simple and generous, the structure is strong and durable. The internal layout is reasonable, the wiring is orderly and standardized, and it is easy to maintain and repair.

It has strong anti-interference ability and can run stably in complex electromagnetic environment.

With a wealth of input and output interfaces, it can flexibly connect various sensors, actuators and other devices to meet diverse control needs.

Simple and convenient operation, through the man-machine interface, users can easily set parameters and monitor the operating status.

Widely used in machinery manufacturing, electric power, chemical industry, metallurgy and other fields, effectively improve production efficiency, ensure production quality, reduce labor costs.

⚙️Product Features

Stable and reliable operation performance

Can work continuously and stably in harsh industrial environment, such as high temperature, high humidity, strong electromagnetic interference, to ensure uninterrupted production process.

Use high quality parts to reduce equipment failure rate.

Excellent anti-interference ability

Effectively shield external electromagnetic interference to ensure the accuracy of control signals.

With a sound grounding and filtering system to reduce the impact of interference on the system.

Efficient cooling design

Install reasonable ventilation and heat dissipation devices, such as fans, heat sinks, etc., to keep the temperature in the cabinet appropriate.

Optimize the internal layout to avoid heat accumulation and ensure normal operation of the equipment.

Reasonable layout and rich interfaces

The internal wiring is orderly and standardized, the equipment layout is scientific, easy to maintain and overhaul.

Provide a variety of types and quantities of input and output interfaces, to meet the connection requirements of different scenarios, with good scalability.

⚙️PLC control cabinet, application in bread baking machine.

First of all, in the preparation stage, the user through the operation panel to set the type of bread, size, baking degree and other parameters, this information will be transmitted to the PLC control cabinet.

The PLC control cabinet then controls the work of the heating element according to the received parameters. It will determine exactly when to start heating, and how much power to heat. For example, in the early stages, in order to allow the dough to ferment, the appropriate temperature and humidity will be provided, and the heating power will be low.

When entering the baking stage, the PLC will increase the heating power and heat up according to the preset time and temperature curve to ensure that the bread crust becomes golden and crisp, and the interior is ripe.

At the same time, it will also control the operation of the mixing motor. In the process of dough mixing, control the speed of the motor and mixing time to ensure the uniform texture of the dough.

Throughout the baking process, the PLC control cabinet continuously receives feedback from the temperature sensor and humidity sensor. If the temperature is too high or too low, it will automatically adjust the heating power to keep the baking environment stable.

Finally, when the baking is complete, the PLC control cabinet will control the machine to issue a prompt tone to inform the operator that the bread has been baked.

In general, the PLC control cabinet makes the operation of the bread baking machine simple, precise and efficient, and can bake delicious bread that meets the requirements every time.

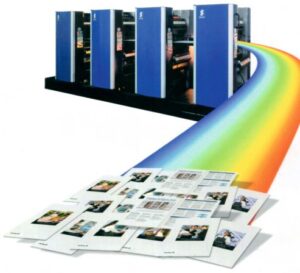

⚙️Application of PLC control cabinet in printing machine.

In the printing press, the PLC control cabinet plays a vital role.

In paper conveying, PLC precisely controls the feeder, adjusting rhythm and strength by paper size and printing speed to ensure smooth, accurate entry to the printing area, preventing jams or skews. For ink supply, it controls each ink hopper’s output by print color and pattern—e.g., boosting ink for darker color prints to ensure saturation and consistency. For plate rotation, PLC ensures precise rotation (per preset speed/position) in sync with paper delivery for clear printing, with real-time monitoring of plate position/speed for instant deviation adjustments.

In addition, for the control of printing pressure, the PLC control cabinet dynamically adjusts the pressure between the printing drums according to the thickness of the paper and the printing quality requirements. If the paper is thin, it will appropriately reduce the pressure and prevent the paper from being damaged;

For cases where a clearer printing effect is required, the pressure is increased to ensure that the ink is adequately transferred to the paper.

Throughout the printing process, the PLC control cabinet will also receive feedback from various sensors, such as paper detection sensors, ink level sensors, etc. If there is an abnormal situation such as running out of paper and insufficient ink, it will issue an alarm in time and suspend the printing press, waiting for the operator to deal with it. For example, when printing a color album, the PLC control cabinet will precisely control the ink supply, plate rotation and pressure according to the different color and pattern requirements of each page, so that each page can achieve high-quality printing effects, and the entire printing process is efficient and stable.

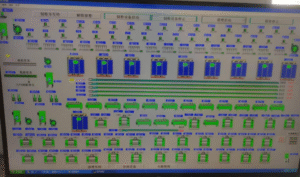

⚙️Applications of PLC in Flour Mill

I. Overview

The programmable logic controller (PLC) is widely used in the field of industrial automation. As a key equipment in the grain processing industry, the flour mill equipment can achieve efficient, accurate and stable operation after the introduction of PLC, which greatly improves the quality and efficiency of flour production.

II. Specific Applications of PLC in Flour Mill Equipment

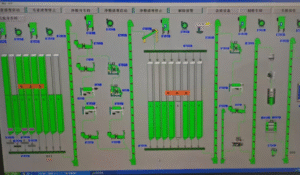

Motor Control

Start and Stop: The flour mill contains multiple motors, such as the grinding motor used to drive the grinding rollers and the conveying motor for transporting materials. Through the PLC, the start and stop control of these motors can be realized in a predetermined order. For example, during startup, the conveying motor is started first to transport wheat and other raw materials to the appropriate position, and then the grinding motor is started to avoid problems such as material accumulation; when stopping, the order is reversed. The grinding motor is stopped first, and then the conveying motor is stopped after the materials are basically processed to prevent residual materials from affecting the next startup.

Speed Regulation: Different processing steps may require the motor to operate at different speeds. The PLC can be connected to a frequency converter to accurately adjust the motor speed according to the process requirements. For example, in the grinding process, for different qualities of wheat or when grinding flour with different fineness, the speed of the grinding motor can be controlled by the PLC to ensure the best grinding effect.

Material Flow Control

Feeding Stage: The PLC can be used in conjunction with electronic weighing sensors and flow sensors. In the feeding stage before the wheat enters the flour mill, the sensors monitor the flow of materials in real time and send signals back to the PLC. Based on the preset feeding amount standard, the PLC accurately adjusts the flow of wheat into the flour mill by controlling the speed of the feeding motor or the opening of the valve, ensuring the uniformity and stability of the grinding process and thus guaranteeing the consistency of the flour quality.

Ingredient Control (if there is a mixture of multiple materials for processing): If other auxiliary materials need to be added during the flour production process, the PLC can also accurately control the addition amount of various auxiliary materials according to the preset ingredient ratio to ensure that the final flour product meets the corresponding formula requirements.

Automated Production Process Control

Operation According to Process Sequence: The PLC strictly controls the sequence of each step in the flour production process, from raw material cleaning, wheat tempering, grinding, sieving to finished product packaging, based on the pre-programmed program. The start, operation time, and stop of the equipment in each step can be accurately controlled to ensure that the entire production process is carried out in an orderly manner, reducing the errors and uncertainties that may be caused by manual intervention.

Remote Control and Monitoring (Optional Function): With the help of the network communication module, the PLC can upload the operating status information of the flour mill equipment to the remote monitoring platform. Managers can remotely view the equipment operating parameters, production progress, etc. in the central control room or through mobile devices, and can also remotely issue control instructions to realize the remote operation of the equipment, which greatly facilitates production management, especially for large flour production enterprises with multiple workshops and multiple sets of equipment.

Reviews

There are no reviews yet.