Description

⚙️Product Description

This is a high-precision, high-performance laser rangefinder.It utilizes advanced laser technology to quickly and accurately measure the distance to a target object, with a wide measurement range suitable for various scenarios.

The surface condition of the workpiece does not affect its detection effect, and it places almost no limitation on the surface color or state of the object, making it effective in detecting a variety of types of objects.

Our laser distance sensor can also detect through gaps or holes in objects, making it suitable for a wide range of applications, including automated measurement in industrial production, distance control in construction, and robot navigation, among others.

⚙️Product Features

High-precision measurement: It can provide measurement results with an accuracy of up to millimeters or even smaller units, ensuring the accuracy of the data.

Independent of Color and Material: The device can accurately measure distances of objects of various colors, textures, and materials, without being affected by their inherent characteristics. For example, it can provide precise data when measuring black rubber and white metal.

Wide Sensing Range: It has a broad measurement range from short distances to long distances, meeting the needs of different application scenarios. For example, it can easily measure distances ranging from a few centimeters to several hundred meters.

Fast Response: It can complete the measurement quickly and provide the results promptly, improving work efficiency.

Good Stability and Reliability: It can maintain stable performance under different environmental conditions, such as temperature changes and humidity differences, and work reliably for a long time.

Low Power Consumption: It is energy-efficient and reduces usage costs and dependence on energy.

Compact and Lightweight: It is easy to install and carry, adapting to various installation locations and mobile application scenarios.

Strong Resistance to Interference: It can effectively counteract the influence of external electromagnetic interference and other factors to ensure the accuracy of the measurement.

Easy to Integrate and Operate: It can be conveniently integrated with other devices and systems, and the operation interface is simple and easy to understand.

⚙️Product Application

1.On the automated production line, objects passing through are detected.

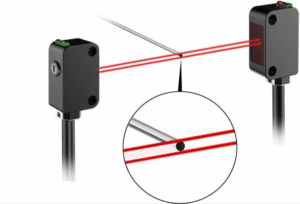

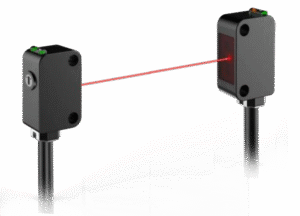

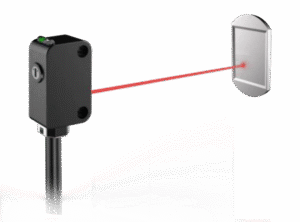

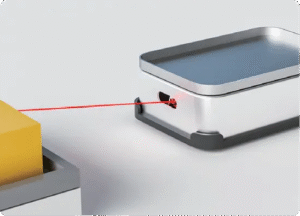

In cases where objects need to be detected as they pass through a production line, laser distance sensors are often used, either through-beam or reflective. A through-beam laser distance sensor consists of an emitter and a receiver, which are installed on opposite sides of the production line. The emitter continuously emits a laser, and the receiver receives the laser. When no object passes through, the receiver can receive the laser signal normally. When an object passes through, the laser will be blocked by the object, and the receiver will not receive the signal, thus judging that an object has passed through. A reflective laser distance sensor, on the other hand, installs the emitter and receiver on the same side, and it emits a laser towards the object and receives the reflected laser. The distance or position of the object can be calculated by measuring the time difference or phase difference between the emitted and received laser.

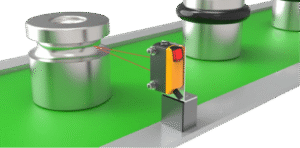

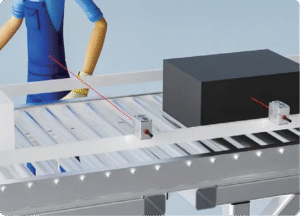

For example, in some automated production lines, reflective laser distance sensors are used to detect objects on a conveyor belt. The sensor is installed at an appropriate position above the conveyor belt, so that the laser beam can cover the area where objects pass through. When a product passes through, the sensor can accurately measure the distance or position of the object and transmit the signal to the control system to achieve counting, positioning, or other related operations. At the same time, we set appropriate parameters and algorithms to ensure that workers operating nearby will not be misidentified. This not only improves production efficiency but also ensures the accuracy and reliability of inspection, while avoiding interference to workers.

2.The position of objects is detected on the automated production line.

In large warehouses, people use laser rangefinder sensors to determine the location of goods on shelves. This is to achieve efficient inventory management and automated retrieval. People install the sensors on the top or side of the shelves. When people store or retrieve goods, the sensors can precisely measure the distance between the goods and themselves. This allows them to accurately obtain the location information of the goods. In this way, the warehouse management system can access the location of goods in real time. This improves the efficiency and accuracy of warehousing operations.

For example, an e-commerce warehouse uses this technology. When people receive new goods, the laser rangefinder sensor quickly detects the location of the goods and transmits the data to the system. This allows workers to quickly locate the goods for outbound operations, greatly reducing the time spent searching for goods.

Reviews

There are no reviews yet.