In the rapidly advancing world of industrial automation, precision and efficiency are paramount. Laser distance sensors are playing a crucial role in meeting these demands by providing accurate, non-contact measurement solutions for a wide range of industrial applications. These sensors, which utilize laser beams to determine distances by measuring the time it takes for the light to reflect back to the sensor, are transforming industries from manufacturing to logistics. This article explores the key contributions of laser distance sensors to industrial automation and their growing importance in modern factories and systems.

Enhanced Accuracy and Precision With HEBEI PROKEY Laser Distance Sensors

One of the most significant benefits of laser range finder in industrial automation is their ability to deliver exceptional accuracy and precision. Unlike traditional contact-based measurement tools, laser distance sensors can measure distances without physical contact, reducing the risk of wear and tear on the sensors and the objects being measured. This is particularly important in environments where high levels of precision are required, such as in quality control, assembly lines, and robotic systems.

The accuracy of laser displacement sensor is measured in micrometers or millimeters, depending on the model, allowing for extremely fine measurements. For example, in a manufacturing setting, laser sensors can be used to precisely measure the position of components during assembly, ensuring that parts fit together correctly. This level of precision is also crucial in industries such as aerospace and automotive, where even the smallest misalignment can lead to defects or failures in the final product.

Automation of Material Handling and Inventory Management With HEBEI PROKEY Laser Distance Sensors

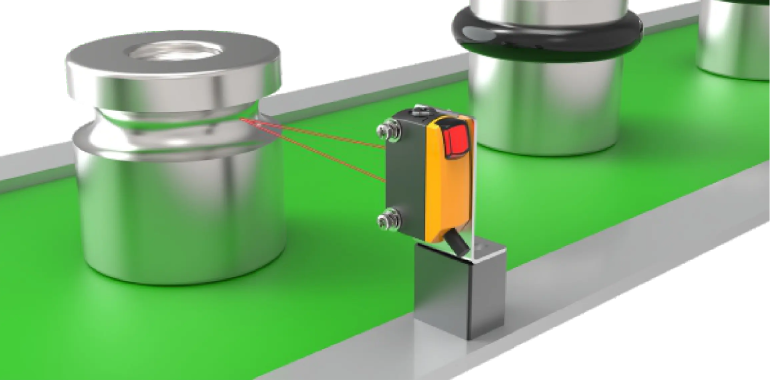

Laser distance sensors play a vital role in automating material handling systems, especially in environments such as warehouses and distribution centers. These sensors are used to measure distances and detect the presence of objects, which is essential for controlling conveyors, robotic arms, and automated guided vehicles (AGVs). By providing real-time data on the location and movement of materials, laser sensors help ensure that goods are moved efficiently and accurately throughout the facility.

In inventory management, laser distance sensors enable automated systems to monitor the height, volume, and position of stock, allowing for more efficient storage and retrieval. For example, in high-bay warehouses, laser sensors can measure the precise height of stacks of goods, helping automated cranes or forklifts adjust their lifting positions accordingly. This not only optimizes space utilization but also enhances the speed and accuracy of inventory processes, reducing the risk of errors and improving overall efficiency.

Improved Safety in Industrial Environments With HEBRI PROKEY Laser Distance Sensors

Safety is a top priority in industrial automation, and laser distance sensors are integral to maintaining safe operations. In environments where large machinery, moving parts, and automated robots are present, laser sensors help detect obstacles and ensure safe distances are maintained between workers and equipment. For instance, in automated production lines or warehouses, laser sensors are often used in collision avoidance systems to detect objects or personnel in the path of robotic arms, AGVs, or conveyor belts.

Additionally, laser distance sensors can be used in safety monitoring applications, such as ensuring that guardrails or barriers are in the correct position or detecting the presence of hazardous objects. The non-contact nature of laser sensors allows for continuous monitoring without the need for physical interaction, enhancing both operational safety and efficiency.

Integration with Other Automation Systems About HEBEI PROKEY Laser Distance Sensors

One of the key advantages of laser distance sensors is their ability to integrate seamlessly with other automation technologies. In modern industrial environments, automation systems are often interconnected to optimize workflows and improve production speeds. Laser sensors are highly adaptable and can be easily integrated into existing control systems, such as programmable logic controllers (PLCs) or supervisory control and data acquisition (SCADA) systems.

By linking laser distance sensors with these systems, manufacturers can automate complex processes such as positioning, measurement, and inspection. For example, in a quality control system, laser sensors can measure the dimensions of a product as it moves through the production line. The data collected by the sensors is then fed into the PLC, which makes real-time adjustments to the production process if necessary. This integration enhances process efficiency, reduces the need for manual intervention, and helps maintain consistent product quality.

Robustness in Challenging Environments About HEBEI PROKEY Laser Distance Sensors

Industrial environments are often harsh, with extreme temperatures, dust, vibrations, and other challenging conditions. Laser distance sensors are designed to withstand these harsh conditions, making them ideal for a wide range of industrial applications. Many laser sensors are built with rugged housings and protection against dust, water, and physical impacts, ensuring reliable performance even in demanding environments.

For example, in heavy industries such as mining or steel production, where high levels of dust, heat, and vibration are common, laser distance sensors continue to provide accurate measurements without being affected by these environmental factors. This reliability is crucial for maintaining the uptime of automated systems and preventing disruptions in the production process.

Advancements in 3D Mapping and Measurement About HEBEI PROKEY Laser Distance Sensors

Laser distance sensors are also instrumental in the advancement of 3D mapping and measurement in industrial automation. The ability to scan objects and surfaces in three dimensions has opened up new possibilities for quality inspection, product design, and reverse engineering. In automated inspection systems, laser sensors can create detailed 3D profiles of components to ensure that they meet exact specifications.

In robotics, laser distance sensors are often used for spatial awareness and obstacle detection, allowing robots to navigate environments more effectively. For instance, in automated welding or painting systems, robots equipped with laser sensors can precisely adjust their position relative to a workpiece, ensuring that every operation is performed accurately and consistently.