Description

1. Exquisite Craftsmanship, Forging Extraordinary Quality

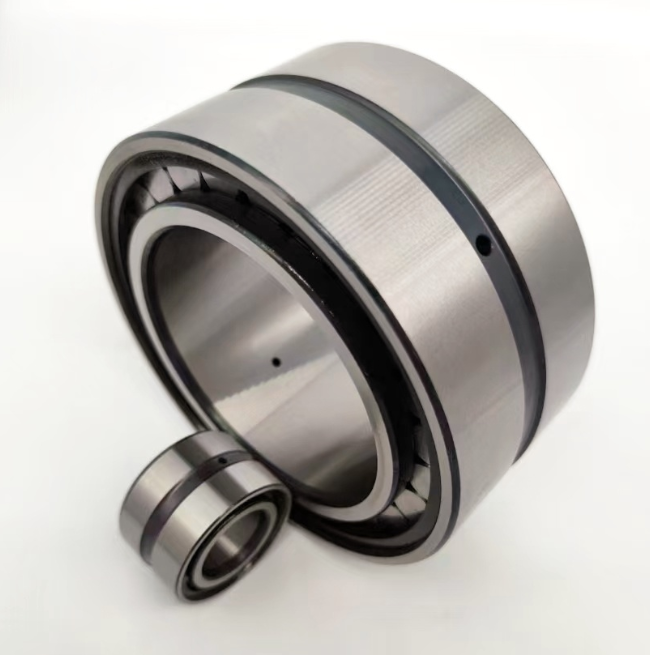

In the manufacturing process of cylindrical roller bearings, FODA strictly adheres to international top standards. Starting from the selection of high-quality steel as raw materials, every processing step has been strictly controlled. Advanced cold and hot rolling technologies ensure the precise formation and uniform size of the rollers; the fine grinding process makes the roller surface as smooth as a mirror, greatly reducing the frictional resistance during operation, reducing wear and prolonging the service life. At the same time, the unique cage design can not only firmly fix the rollers but also ensure the flexibility of the rollers during high-speed operation, laying a solid foundation for the excellent performance of the entire bearing.

2. Strong Load Capacity, Adaptable to Multiple Scenarios

Thanks to its unique structural design, the cylindrical roller bearing has an extremely strong radial load-bearing capacity, enabling it to handle various harsh working conditions with ease.

- In the heavy machinery field, such as large crushers in mining and giant cranes in port loading and unloading, FODA cylindrical roller bearings shoulder heavy responsibilities.

- In the industrial machine tool industry, lathes, milling machines and other equipment have extremely high requirements for processing accuracy.

- In the power equipment category, whether it is a steam turbine in thermal power generation or a hydraulic turbine in hydropower generation, high-speed rotation and bearing huge loads are the norm.

3.Technology Leadership, with All Technical Parameters Clearly Visible

3.Technology Leadership, with All Technical Parameters Clearly Visible

To meet your in-depth exploration of product details, we have thoughtfully built a convenient access channel. Just click on the link https://www.fodabearing.com/, and you can directly access the FODA official website, where you can comprehensively consult the detailed technical parameters of the cylindrical roller bearings, including roller size, pitch circle diameter, rated dynamic load, limit speed and other core indicators. The accurate parameter information will help you select the most suitable bearing model for your equipment, ensuring that every selection is just right.

Reviews

There are no reviews yet.