Description

⚙️Product Description

In modern society, the shape of industrial products is more and more diverse, complicated and personalized, which undoubtedly brings huge challenges to industrial three-dimensional testing. When faced with products with complex surface modeling, it is extremely difficult to achieve full-scale inspection. In particular, for parts with soft surfaces, unstable surfaces or extremely complex contours, contact measurement solutions are simply not suitable, and there is an urgent need for professional non-contact, full-size quality inspection solutions. 3D laser profile scanning is the perfect solution to these problems.

⚙️Product Features

1: With fast data acquisition ability, a single image to obtain millions or even tens of millions of points of topography data. Scan table 360° rotation, no dead corners to obtain full circle real 3D data. Greatly improve work efficiency.

2: With extremely high accuracy, it can accurately capture the fine features and contour changes of the surface of the object. The linearity can reach ±0.02%. The advantage is more obvious when the measurement of high-low difference objects and the location of the measurement objects change

3 The non-contact measurement method avoids the damage to the measured object, ensures the integrity of the object, and has a strong adaptability, can work stably in a variety of complex environments.

4: Meet the IP67 standard, even in a humid and dusty environment, but also safe to use.

5: Can accurately measure black objects with low reflectivity and metal objects with high reflectivity at the same time.

6: Brightness can be automatically optimized without the help of external light sources.

7: The use of high toughness cable, which can withstand up to 30 million bends, equipped with the machine.

⚙️Product Application

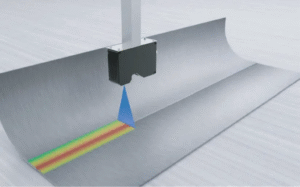

1.Weld Seam Shape Detection

Three-dimensional laser profile scanning can accurately detect the shape, width, depth and other parameters of the weld, determine whether the weld is uniform and continuous, and whether there are porosity, slag inclusion, incomplete penetration and other defects, so as to evaluate the quality of the weld.

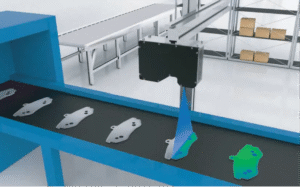

2.Stamped Parts Inspection

Use 3D laser profile scanning sensor to detect the size, shape, width, height, etc., to determine whether there are burrs, wrinkles, cracks, surface scratches, bumps, etc.

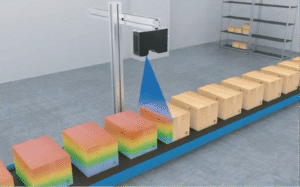

3.Product Outer Packaging Inspection

Three-dimensional laser contour scanning is used to detect the outer packaging of boxed products to determine whether the outer packaging is damaged, deformed, poorly sealed, whether there is any stain, whether it is damp, whether the mark is correct and so on.

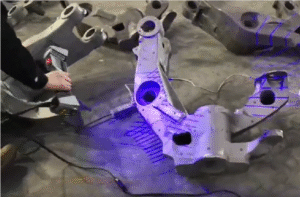

4.Application of handheld scanners in castings

Using 3D laser profile scanning, you can detect mold wear, corrosion, poor demoulding, gate defects, core fracture, uneven cooling and other defects

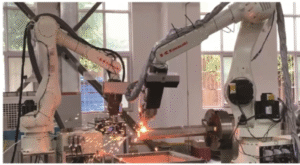

5.Robot Arm Guidance

3D laser profile scanning can provide high-precision object surface profile information to help the robot arm accurately determine the position and posture of the object to grasp, operate or process. For example, in an assembly job, a robot arm can accurately grab and place a part based on scanned data about its shape and position. By scanning the working environment and the target object, the robot arm can obtain detailed spatial information to optimize the motion path. This helps avoid collisions, reduce exercise time, and increase productivity.

6.Tire Inspection

The 3D laser profile scanning sensor can find defects such as cracks, bubbles, uneven wear and foreign body embedding on the tire surface, and accurately measure key dimensions such as the tire’s outer diameter, inner diameter, tread width, side thickness, and pattern depth to ensure that the tire meets the design specifications and quality standards.

Reviews

There are no reviews yet.